- Details

Medical Products Injection Mold

Equipment Overview

Medical injection molds have high requirements for structure and appearance. High strength can extend the service life of medical products, and smooth surface can provide better comfort for hand operation.

In order to meet the structural and appearance requirements, we should choose the right materials and adopt the right injection molding design to produce high-quality medical components. Considering the unique applications of medical molds and products, the entire production line must be kept clean and free of contamination.

Lixun Overall Strength Guarantee Lixun has independent R&D engineering team, software team, mold team, machine adjustment team, complete team composition and strict quality control system; | Having Both Soft And Hard Based on the needs of Chinese people, by replacing force sensors with different ranges and accurately controlling the force, the same product can be made into soft and hard plastic products. |

Manufacturing Experience Lixun has 25 years of experience in intelligent manufacturing and a 30-acre production base. Based on a deep understanding of customer pain points and needs, we have formed a professional team to develop more cost-effective all-electric products; | Advanced Software The software is built on the CODESYS platform, with real-time animation display and connection via ETherCAT. The communication time is less than 2ms, and the data can be uploaded to the cloud server after being connected to the MES system. |

Features

1. High precision

Medical devices have extremely high requirements for dimensional accuracy and consistency. Injection molds must be able to achieve micron-level accuracy to ensure that the product meets medical standards and avoid errors that cause functional failure.

2. Strict hygiene requirements

Mold materials and processing technology must meet the hygiene requirements of the medical industry. Usually, high-quality materials that are corrosion-resistant, not easy to contaminate, and easy to clean, such as stainless steel or special alloys, are required.

3. Adapt to diverse materials

Common injection molding materials for medical products include medical-grade plastics (such as PC, PEEK, PP, etc.). Mold design needs to consider the fluidity, shrinkage and heat resistance of the material to ensure stable performance of the finished product.

4. Complex structural design

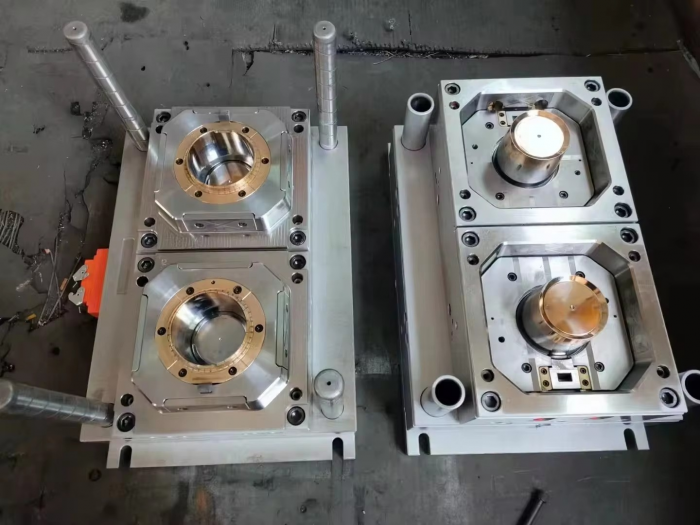

Medical products are usually precise in structure and complex in function. Molds need to have delicate flow channel design and efficient exhaust systems to meet the manufacturing needs of complex products.

5. High durability and stability

Since medical products need to be mass-produced, molds need to have good wear resistance and long-term stability, reduce replacement frequency, and ensure production efficiency.

6. Compliance with regulations and certifications

The medical device industry has strict regulatory requirements for production tools (such as ISO13485 and FDA standards), and the design and manufacture of molds must comply with these certification standards.

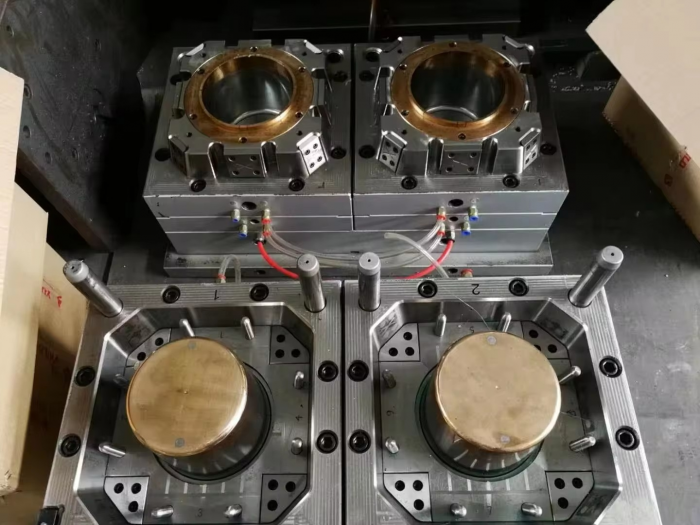

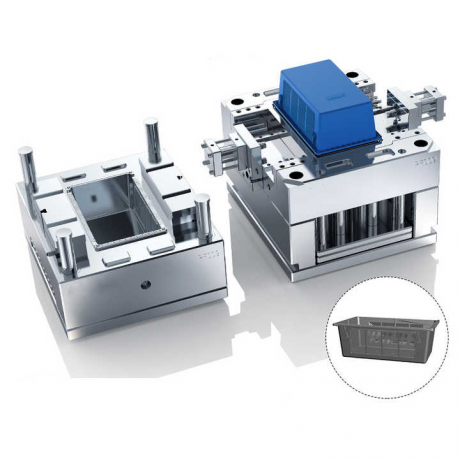

7. Multi-cavity design

To improve production efficiency, medical molds usually adopt a multi-cavity design, so that a single injection molding can produce multiple products, but the consistency of each cavity product must be guaranteed.

8. Efficient cooling system

Medical molds need to be equipped with advanced cooling systems to shorten the molding cycle and ensure that the product is quickly molded and maintains high quality.

9. Automation and intelligence

Modern medical mold design tends to integrate automation devices (such as demoulding mechanisms, sensors, etc.) to achieve efficient and intelligent production and further reduce manual intervention.

10. Customization capabilities

There are many types of medical products, from surgical tools to implants, and molds usually need to be customized according to the special functions of different products to meet personalized needs..

Technical Parameters

Product Name | Plastic parts Medical injection mold |

Material | ABS, PC, PP, PS, POM, PMMA,PBT,PVC,PA6,PA66,PA66+30%GF, |

Surface Finish | Color painting,Texture,Silk-printing,Vacuum coating,rubber coating, etc. |

Cavity Variety: | One-stop solution,Multi-cavity mold,Family plastic mold,Hot runner plastic mold |

Quality Control | ISO/TS16949:2002 and ISO14001:2004 system |

Business Scope | Mold and parts designing and making,Parts machining,Injection molding, |

Mold Processing | CNC EDM machine processing then assembly and trial |

Color | Red, blue, green, yellow,all pantone colors and RAL colors |