- Details

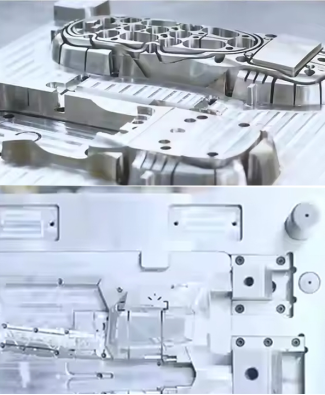

Auto Parts Injection Mold

Equipment Overview

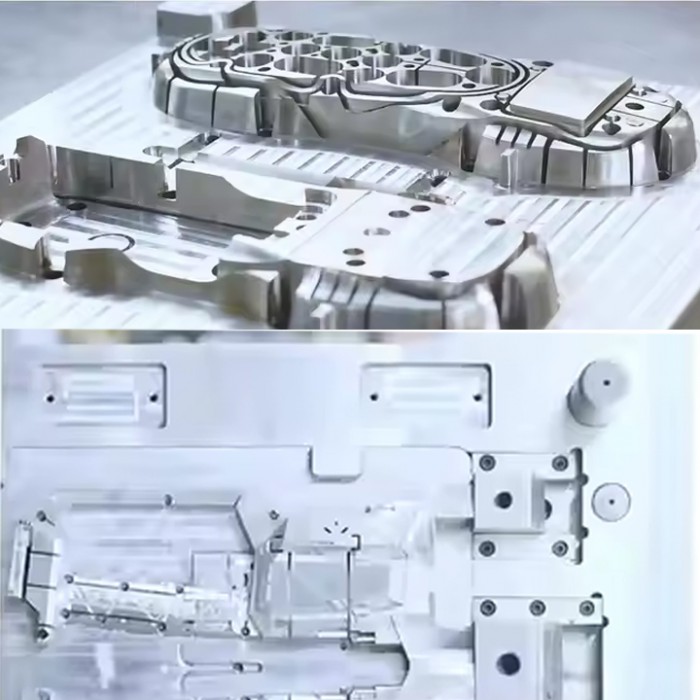

Automotive injection molding is a tool that uses an injection molding machine to inject molten plastic material into a mold, and after cooling and solidification, it forms the required automotive parts.

Processing technology: The heated and melted material is taken into the mold cavity under a certain high pressure, and then after a certain cooling treatment, the molded product of the automobile injection mold is obtained. This is a combined mold, which is mainly composed of a gravure combined substrate, etc., and can be processed into automobile injection molds of different shapes and sizes according to the specific needs of users.

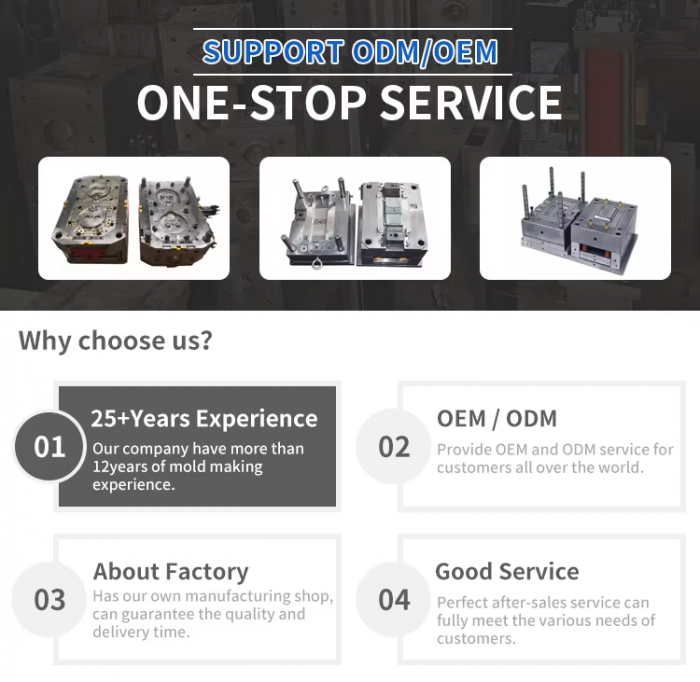

Lixun Overall Strength Guarantee Lixun has independent R&D engineering team, software team, mold team, machine adjustment team, complete team composition and strict quality control system; | Having Both Soft And Hard Based on the needs of Chinese people, by replacing force sensors with different ranges and accurately controlling the force, the same product can be made into soft and hard plastic products. |

Manufacturing Experience Lixun has 25 years of experience in intelligent manufacturing and a 30-acre production base. Based on a deep understanding of customer pain points and needs, we have formed a professional team to develop more cost-effective all-electric products; | Advanced Software The software is built on the CODESYS platform, with real-time animation display and connection via ETherCAT. The communication time is less than 2ms, and the data can be uploaded to the cloud server after being connected to the MES system. |

Classification

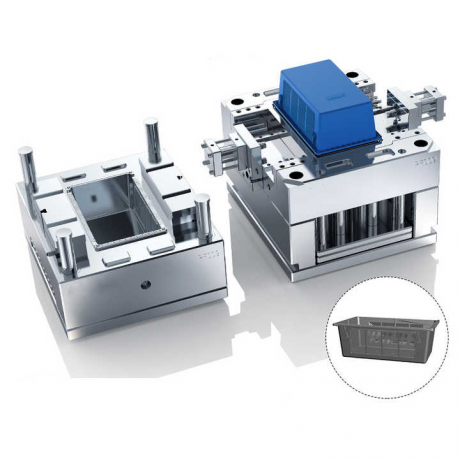

According to different uses and processes, automotive injection molding can be divided into interior parts molds, exterior parts molds and structural parts molds, etc.

Application

Interior parts: such as dashboards, door panels, seats, etc.

Exterior parts: such as bumpers, fenders, rearview mirror housings, etc.

Functional parts: such as various plastic parts under the hood, such as intake manifolds, fuel filter housings, etc.

Features

High precision: ensure the dimensional accuracy and surface quality of parts.

High efficiency: improve production efficiency and reduce production costs.

Strong flexibility: adapt to the production of parts of different shapes and complexities.

Technical Parameters

Pls provide | 2D, 3D, samples, or the size of the multi-angle pictures |

Mould Time | 20-45 Days |

Product time | 7-15 Days |

Moud precision | +/-0.01mm |

Mould life | 50-100 million shots |

Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode |

Mould cavity | One cavity, multi-cavity or same different products be made together |

Mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

Runner system | Hot runner and cold runner |

Base material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

Finish | Pitting the word, mirror finish, matte surface, striae |

Standard | HASCO, DME or dependent upon |

Main technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

Software | CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

Product material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

Quality system | ISO9001:2008 |