- Details

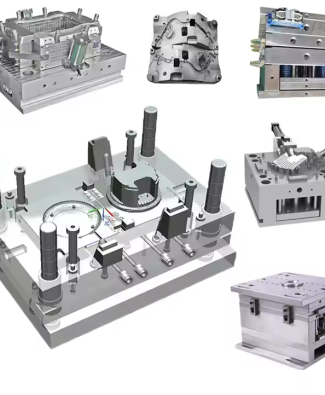

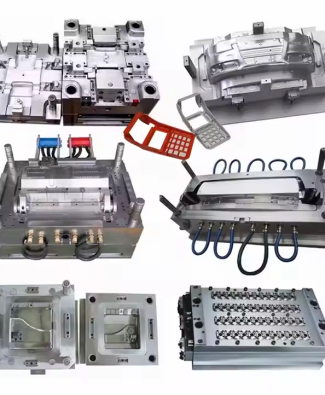

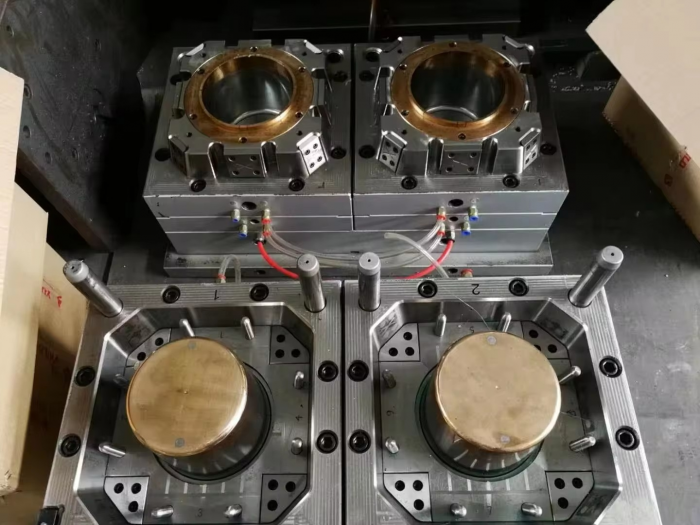

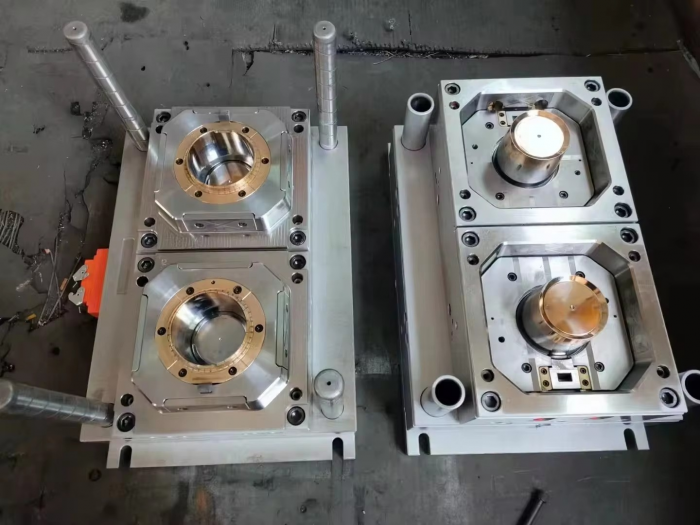

3C Electronic Parts Injection Mold

Equipment Overview

3C product injection molding is widely used in the electronics industry, especially in high-precision manufacturing. 3C products include computers, communication equipment and consumer electronics, which have extremely high requirements for appearance and performance. Injection molding technology can achieve high-precision parts production, ensuring that the size and shape of the product meet the design requirements. High-precision mold manufacturing and injection molding processes ensure the appearance quality and structural strength of 3C products, meeting the market demand for high-quality products.

Lixun Overall Strength Guarantee Lixun has independent R&D engineering team, software team, mold team, machine adjustment team, complete team composition and strict quality control system; | Having Both Soft And Hard Based on the needs of Chinese people, by replacing force sensors with different ranges and accurately controlling the force, the same product can be made into soft and hard plastic products. |

Manufacturing Experience Lixun has 25 years of experience in intelligent manufacturing and a 30-acre production base. Based on a deep understanding of customer pain points and needs, we have formed a professional team to develop more cost-effective all-electric products; | Advanced Software The software is built on the CODESYS platform, with real-time animation display and connection via ETherCAT. The communication time is less than 2ms, and the data can be uploaded to the cloud server after being connected to the MES system. |

Material selection

Common injection molding materials include ABS, PC, PA, POM, etc. These materials have excellent mechanical properties, heat resistance and chemical corrosion resistance.

Features

(1) High precision: The manufacturing precision of 3C digital injection molds is very high, reaching the micron level, so high-precision products such as mobile phones, tablets, digital cameras, etc. can be produced.

(2) High quality: Due to the high manufacturing precision of 3C digital injection molds, the quality of the products produced is also very high, with a smooth surface and no defects, which can meet the needs of consumers.

(3) High efficiency: The manufacturing process of 3C digital injection molds is very fast and can be processed by modern CNC machine tools, which can greatly shorten the manufacturing cycle and improve production efficiency.

(4) Diversification: 3C digital injection molds can produce a variety of different products, so they can meet the needs of different customers, and can also quickly launch new varieties according to market demand.

(5) High stability: The mechanical properties and thermal stability of 3C digital injection molds are very high, so long-term stable production can be guaranteed.

Technical Parameters

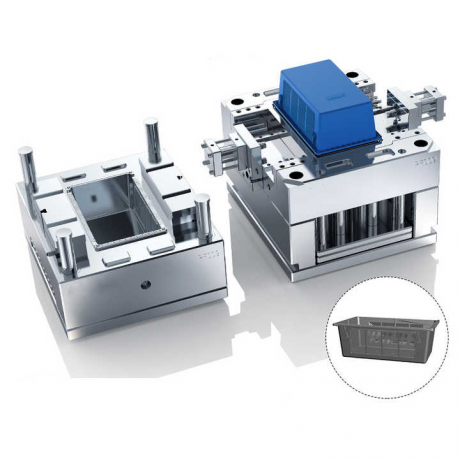

Product | Moulds |

Material | ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT |

Product Name | Plastic injection moulds |

Mold Material | P20/718/738/NAK80/S136/2738/2316/etc |

Plastic Cavity | Single cavity or multi-cavity |

Mold Runner | Cold or runners |

Mold Frame | LKM, HASCO, DME as your requirements |

Color | Colors |

Dimensions | Customized sizes |

Cavity | Multi-cavity |

Gate Type | Side gate, sub-gate, pin-point gate, edge gate, etc. |

Sales Unit: | Single commodity |

Packaging Size: | 10*10*10 cm |

Gross Weight | 1kg |